HV-MELA-BAT

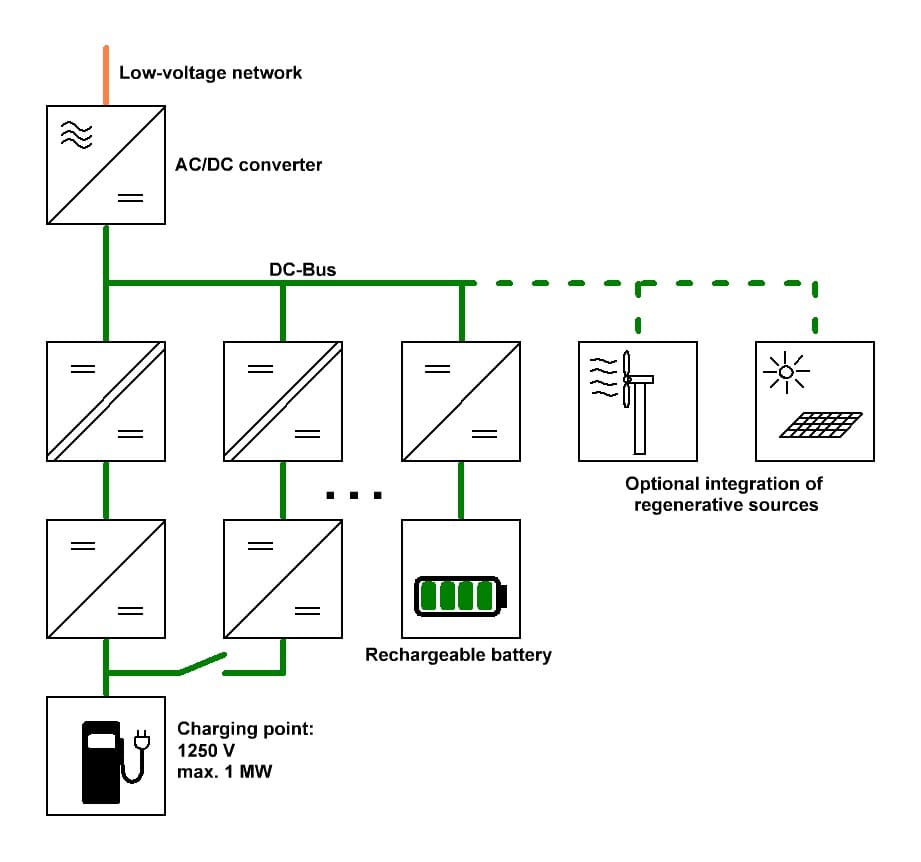

In the BMWK funded project HV-MELA-BAT a high voltage megawatt charging system for heavy duty and passenger transport is developed, which allows increased charging power at high charging voltages of up to 1250 V at the same time.

M&P’s task here is to develop the Active Front-End Converter (ACDC converter) as the interface between the power grid and the internal DC grid, the buck converter (DC/DC converter) for variable charging voltage adaptation to the vehicle and the buffer storage. The project will also develop a bidirectional and isolated converter. For this purpose, LT250 generation converters based on SiC technology will be further developed. This enables higher clock frequencies and thus smaller packing densities of the converters.

The project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK).

For more information, see: https://www.ise.fraunhofer.de

Lade-PV

In the funded project Lade-PV, the integration of photovoltaics in commercial vehicles is to be developed for widespread use. To this end, the project partners have developed photovoltaic modules that can be integrated into the box body of the commercial vehicle. The modules are connected in series. This allows system voltages of up to 800 V to be achieved at low currents.

M&P developed a DC-DC converter that connects the photovoltaic system to the traction battery of the commercial vehicle. The converter was deeply integrated into the vehicle system so that the optimal operating strategy is set for each vehicle condition. In the event of an accident, a safe condition is established.

The DC/DC converter has an integrated MPP tracker that is capable of handling dynamic shading conditions, such as those that occur when driving through alleys or bridges.

When the system is not active or in a fault condition, the PV modules are disconnected and have a non-hazardous voltage of less than 60V.

The converter has an output of 4 kW and is passively cooled at an ambient temperature of -40 °C to 90 °C.

For more information on the collaborative project, see: https://www.ise.fraunhofer.de/

GUW+

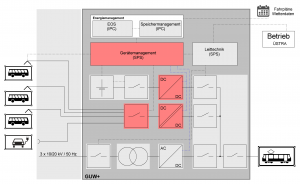

In the funded project GUW+, a regenerative and controllable DC substation is being designed that connects the electric power supply infrastructure of light rails and trams with charging stations for electric buses. In addition, a battery storage system made of 2nd-use vehicle batteries from electric buses will be installed in the GUW+, which can avoid peak loads and temporarily store excess braking energy from light rail operations and make it available as needed.

Within the project, a GUW+ will be realized in cooperation with the Hannoversche Verkehrsbetriebe (ÜSTRA) in Hannover Döhren, demonstrating and evaluating the functions.

M&P delivers systems for a compact charging infrastructure with isolated DC/DC converters in power stages of 75 kW and output switching matrix for flexible connection of several charging points. Furthermore, bidirectional buck-boost converters for the connection of the battery storage are developed and delivered. Furthermore, M&P contributes to the control side information networking in the GUW+ with gateway and device management functions in a central PLC.

The GUW+ project has received funding from the Federal Ministry of Transport and Digital Infrastructure (BMVI) within the funding program Electric Mobility. The program is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

For more information, see: https://guwplus.de

Rail Brake Drive and Control System 2 (RDCS 2)

The brake drive and control system 2 (BASS 2) is an electric drive system for the operation of electrodynamic track brakes in shunting mode. By providing the peak power of the electrodynamic track brakes (up to 4 x 400 kW simultaneously) via a high-performance energy storage system, the power consumption from the mains can be reduced to a maximum of 80 kVA. The very low energy consumption and the low connected load required result in significant cost savings for the power supply.

The power electronics of the BASS are designed with multiple redundancy from the feed-in to the power output, thus achieving high availability. In the event of a power failure, the buffer storage serves as a UPS to ensure a safe shutdown. The BASS 2 is virtually maintenance-free and achieves safety level 1 (SIL 1). Due to the high availability and the very low maintenance effort, the costs over the entire lifetime of the plant (LCC) are very low.

For detailed information, please see:

https://gruen.deutschebahn.com/en/measures/electrodynamicbrakes

Contact form

For questions, suggestions or project inquiries please use our contact form. We get in contact with you as soon as possible.

| Telefon: | +49 351 323305-10 |

| Fax: | +49 351 323305-19 |

| E-Mail: | info@powerelectronics.de |

M&P Motion Control and Power Electronics GmbH

Bismarckstraße 56

01257 Dresden